News

Thomas Halken appointed CEO of IWAKI Nordic A/S

6/1 2025

Introduction of two new and powerful pump sizes in the MDM series

9/4 2021

IWAKI Pumps obtains European food approvals

16/11 2020

Contact us like you usually do!

18/3 2020

IWAKI Japan is prepared and reassures customers

18/2 2020

Thomas Halken joins IWAKI Nordic A/S

30/4 2019

IWAKI reveals new R&D center in Tokyo

6/3 2019

Product launch at Achema 2018

22/6 2018

IWAKI Pumps since 1956

22/11 2016

First Aid in case of Chemical Exposure

26/5 2016

Thomas Halken appointed CEO of IWAKI Nordic A/S

6/1 2025

Thomas Halken takes over the role of CEO from founder Jan Feddersen, who has led the company for more than 30 years. During this time, the company has grown significantly—thanks in large part to the core values Jan has implemented: high product quality, local supply across the Nordic region, and well-qualified customer support from a dedicated Nordic team.

Thomas originally trained as a chemical engineer and brings over 25 years of management experience from companies such as ThyssenKrupp Elevator A/S, EGN Denmark, and Gestenberg. Over the past five years, he has served as COO at IWAKI Nordic, building a deep understanding of the company and the values that define it.

Introduction of two new and powerful pump sizes in the MDM series

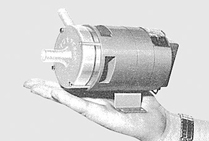

Pump types: MDM40-2 & MDM50-2

9/4 2021

IWAKI has developed two new pumps for the MDM series with a max. flow of 1,800 l / min.

With the introduction of these pumps, the MDM pumps cover a much wider area, where the larger MDE pumps were previously preferred.

The MDM40-2 & MDM50-2 pumps have a high efficiency compared to similar magnetically driven pumps.

A new impeller design also reduces the risk of cavitation.

IWAKI Pumps obtains European food approvals

16/11 2020

The food approvals have been carried out on two of IWAKI’s standard pump types.

IWAKI Nordic A / S can now offer magnetic driven centrifugal pumps and dosing pumps approved for the food industry and for the pharmaceutical industry. These are IWAKI’s MDM pump series and dosing pumps in the LK-F5 series.

In connection with the approval (according to EN 1935/2004 and EU 10/2011), IWAKI has used the recognized company SGS Institut Fresenius for the migration analyzes. SGS Institut Fresenius has performed 12 migration analyzes with different simulants (acetic acid, ethanol, isooctane and water).

The approved centrifugal pumps have wet-end parts of PFA, PTFE and SiC while the metering pumps use PTFE membranes and gaskets.

Contact us like you usually do!

18/3 2020

IWAKI is aware of the great responsibility we have in relation to keeping the industry’s production equipment running even in the situation with Covid19.

Therefore, we would like to reassure all our customers that critical work functions at IWAKI continue unchanged so that deliveries of pumps, spare parts and more is secured in an almost normal manner.

Some staff work from home, and everyone follows the authority’s advice to avoid infection. We are reached in the usual way, either by phone or email. See staff list

We receive and deliver daily goods at our Nordic main warehouse in Hillerød, Denmark. We prioritize security of delivery, both by maintaining our already good stock and by having key personnel in place.

From Japan, we can tell that the production at IWAKI’s factories goes as normal, some suppliers have actually reopened production and deliveries to our factories.

IWAKI Japan is prepared and reassures customers

18/2 2020

Several customers have asked if IWAKI production and logistics is threatened by the Corona virus, which currently is mainly ravaging in China. We can reassure that the vast majority of IWAKI’s pumps are ‘purely Japanese’ and production and logistics is not affected.

In the few cases where components from China are used, IWAKI has sufficient stock for many months of pump production.

We are monitoring the situation and are constantly updating our precautions.

Product launch at Achema 2018:22/6 2018 Two new EJ dosing pumps from IWAKI |

|

| IWAKI launched two new pump sizes in the EJ dosing pump series at the Achema exhibition in Frankfurt. These electromagnetic dosing pumps have almost tripled the flow capacity for the EJ series. The EJ series is now offered in six pump sizes. | |

|

The EJ series covers a wide capacity area from the small B09 pump size with max capacity of 1,14 l/h to the large B31-L size with a max capacity of 12 l/h.

The pumps manages a maximum pressure of up to 1.2 MPa depending on the pump size. The wet end parts are made of materials with excellent chemical resistance. New EJ pump sizes B31 and B31-L was |

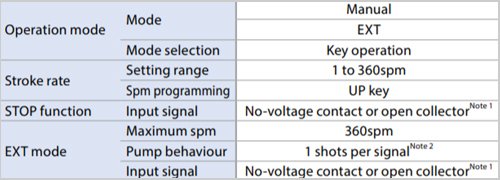

Controller optionsIn the EJ series you can adjust the stroke speed between 1-360 strokes per minute providing high resolution chemical feed and high turndown capability. In addition to the stroke rate, several other control options are also available. |

|

Explanation of the notes can be found in the brochure |

|

| Read more | |

IWAKI Pumps since 1956

26/5 2016

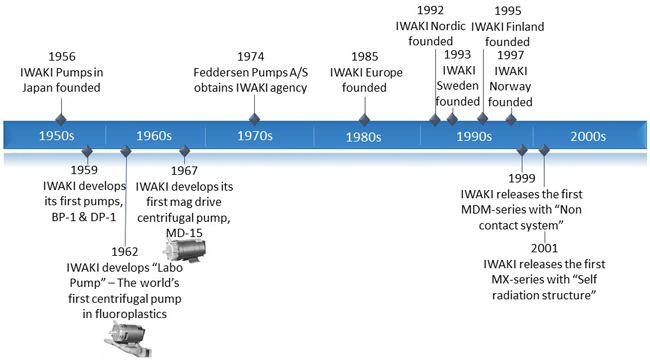

| The Japanese engineer Yoshiaki Fujinaka founded IWAKI in 1956 in Tokyo and 2016 marks IWAKI’s 60th anniversary. IWAKI recently celebrated its anniversary with a festive gathering for all employees in Japan. | |

|

|

From distributor to manufacturerIWAKI was originally founded as a physics and chemistry appliances trading company, but offered many other products such as TV’s and washing machines, which was regarded as luxury goods at that time. |

|

|

Nevertheless, IWAKI’s main occupation remained chemistry appliances, and during the first many years, they focused on selling “shakers” for use in laboratories. In the 1950’s, laboratories and the chemical industry began to apply solvent extraction as a new analytical method, which led to an increase in demand for shakers.

IWAKI had through sale of shakers gained significant insight and experience with these appliances and knew, a way to increase profits, was by turning into a manufacturer. IWAKI saw the increasing demand as an excellent opportunity, and after several weeks of internal meetings, brainstorming and assistance from a well-known professor, IWAKI invented its first shaker. |

| “KM type universal shaker”. | |

The pump adventure begins |

|

| IWAKI developed its first two pumps in 1959. DP-1, a diaphragm pump and BP-1, a bellows pump complemented the physics appliances well as the wetted parts were made from fluoroplastics. It enabled the pumps to cope with aggressive fluids.

The beginning of the 1960s became a turning point for IWAKI. An increasing interest and demand in low-flow chemical pumps made IWAKI change direction. IWAKI changed to focus solely on production of pumps. |

|

| The company’s breakthrough appeared in the wake of the changed direction, as Yoshiaki Fujinaka invented “Labo Pump” (LP1), the world’s first centrifugal pump in fluoroplastics. The newly developed pump was reliable, small and compact, and for this reason very suitable for implementation (OEM).

In 1962, IWAKI received its first order of LP1 for implementation in vending machines. Within short time, several Japanese manufacturers had implemented the pump. Click here to read the full story about IWAKI and the vending machines. |

|

| The images shows: – IWAKIs DP-1 pump from 1959 – IWAKIs LP-1 pump from 1962 |

|

IWAKI’s first magnetic drive centrifugal pump |

|

| In 1967, IWAKI developed MD-15, the very first magnetic drive centrifugal pump made from fluoroplastics. The pump has today obtained “icon status” as the MD-series is still in production. Moreover, MD-15 had many similarities with LP1; small, compact but this time even more reliable!

The magnetic coupling ensures a hermetically sealed pump chamber in contrast to sealed centrifugal pumps, which over time can become worn-out and leak. Click here to read the difference between magnetic drive centrifugal pumps and sealed centrifugal pumps. |

|

Focus on qualityAn IWAKI pump is very reliable and dependable. Right from the start, IWAKI has emphasized the importance of quality control and assurance which is deeply integrated and rooted in the company culture, and ranges from quality control in working processes to quality assurance of spare parts. Furthermore, all IWAKI pumps has to meet stringent quality requirements, and passes as a minimum a trial run and a visual inspection. Research & DevelopmentAround 20% of IWAKI’s employees engage in research and development of new products and technologies. The R&D department co-operate with the sales and marketing dep., which on an ongoing basis gathers customer feedback and analyze the market. This ensures the R&D dep. always to be at the forefront of technological innovations. IWAKI todayIWAKI has been subject to a rapid development since the invention of the first mag drive centrifugal pump. Today IWAKI is a transnational corporation with subsidiaries, joint ventures and distributors in more than 30 countries around the world. IWAKI’s key competence lies within magnetic drive centrifugal pumps and dosing pumps, and IWAKI’s assortment of pumps encompass more than 60 pump series and over 600 variants. |

|

Premiere of a chemical safety course

26/5 2016

Protecting the environment and personal safety are key objectives for IWAKI Nordic A/S which was the theme in the extended course for the chemical industry is developed by Soren Pilemann from Cardiocare together with IWAKI’s technical manager Hans-Peder Jensen. Main focus was the “Top 10 chemicals” in the industry. On the agenda was:

- Chemicals and risks

- Safety datasheets / work environment

- Personal protection

- Health injuries

- Acute injuries

- Long-term effects

- Fire / spillage / waste

- Tips

An important step in the effort to fully live up to IWAKIs Mission Statement which clearly and unambiguously explains IWAKI’s objectives:

IWAKI helps you handling your aggressive, flammable and toxic fluids in a safe and responsible manner.

To protect the environment and in particular to protect you and your surroundings.