Existing solutions optimize use of chemicals and increase safety

while research finds alternative solutions

Reports are written and research projects initiated on various process areas to clarify and to develop workable alternative process solutions for companies using hazardous chemicals.

By finding process solutions where the use of chemicals is minimized or avoided, the health risk for the employees handling the hazardous chemistry will be improved. For example, a lot of research is being done into wastewater treatment, where the industry is currently using chemicals in the process.

With proven solutions, IWAKI offers to optimize the use of chemicals still used in existing technologies. At the same time, the safe handling of the aggressive liquids is ensured for the benefit of both humans and the environment.

The picture shows a fully automatic dosing cabinet with four IWAKI IX pumps at Fredericia Wastewater.

The chemistry is dosed so that the sludge is precipitated and can be used in e.g. biogas plants.

The cabinet was installed in 2019 together with a 30m3 chemical tank (seen in the background).

Example from the WasteWater area

A few years ago, the Danish Environmental Protection Agency released the report ’‘From wastewater to phosphorus-containing products’ (in Danish). In the report wastewater is considered as both a resource and a waste product, as wastewater contains both valuable nutrients (including phosphorus) but also impurities. It is therefore important to handle the waste water correctly to get the most out of the resource.

At the same time the desire to reduce the use of precipitating chemicals (optimization of chemicals by chemical dosing) is mentioned. For some years research has been conducted with electrocoagulation as a substitute for iron chloride in wastewater treatment.

Recently, the Danish research project ‘Elektrosep’ has been mentioned in the medias, where The Danish Technological Institute and Aalborg University participate in a wastewater project with the desire for a safe working environment and an environmentally friendly solution.

Read more (in Danish).

|

IWAKI solutions – tried and tested

Referring to the example above IWAKI has for several years delivered dosing cabinets for e.g. iron chloride.

The chemical dosing is controlled by dosing pumps delivering exactly the amount of iron chloride needed for the process – neither more nor less.

It runs automatically and the process is protected in a closed cabinet. There is no risk to personnel and there is no waste of chemicals.

Read more

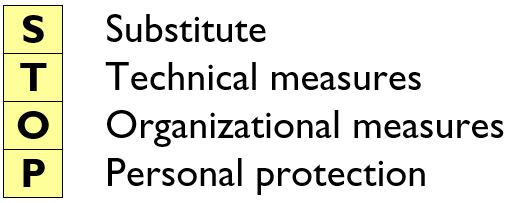

Substitution or technical measures

If you work with dangerous chemicals, you might have sought a replacement product for your chemicals, as prescribed by the Danish Working Environment Authority for the sake of people and the environment.

But maybe there is no viable alternative, and you are therefore looking for well thought out and tested technical measures…

By using IWAKI’s secure technical solutions, your business can

- Continue working unimpeded

- Protect employees

- Secure the surroundings

- Protect the environment

- Meet the requirements of the authorities

- Support several of the UN Global Goals

With IWAKIs solutions your company contributes to several of the UN Global Goals

(Read more)

- SDGs 6: Clean water and sanitation

- SDGs 8: Decent work and economic growth

- SDGs 9: Industry, innovation and infrastructure

- SDGs 12: Responsible consumption and production