Vacuum lifting systems

A suction solution when using centrifugal pumps.

A suction solution when using centrifugal pumps.

Vacuum lifting systems can be used as a simple solution to ensure correct suction for centrifugal pumps by transporting liquid from tanks or containers up to the pump.

Background

Pump prices depend on pump type and specifications, including the pump’s self-priming ability.

For safety reasons, the liquid is often transported up and through the top of the tank, which gives a long suction distance – especially if the pump is located far away. This solution results in heavy demands on the type of pump and, if necessary, a separate priming chamber/suction tank.

An alternative solution could be a vacuum lifting system, where the lifting system is placed at the top of the tank to elevate the liquid.

The vacuum lifting system ensures a steady liquid supply to the pump, as long as there is liquid in the tank. The lifting system can be combined with an alarm.

Automatic or manual suction

The lifting system is available in 2 versions with either manual or automatic suction.

For both systems, a vacuum is built up in the lifting system at the tank outlet pipe. The system is available both as a manual system, where you build up a vacuum yourself in the vacuum container, and as an automatic system powered by compressed air. Thus, the liquid is elevated to the pump and further into the system.

The unit is supplied in PVC or silicate glass, with gaskets in EPDM/FKM. Fittings are DN15.

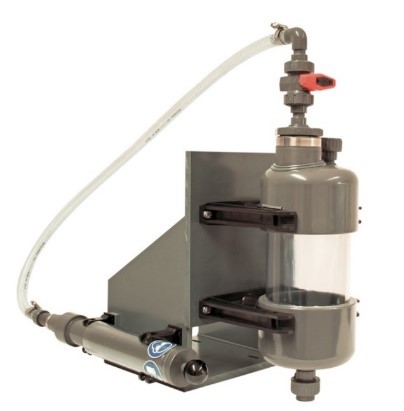

Figure 1: Manual vacuum lifting system

The manual system consists of a hand pump, where the liquid is manually lifted up to the system.

Figure 2: Automatic vacuum lifting system

The automatic vacuum lifting system lifts the liquid up to the system, using compressed air.