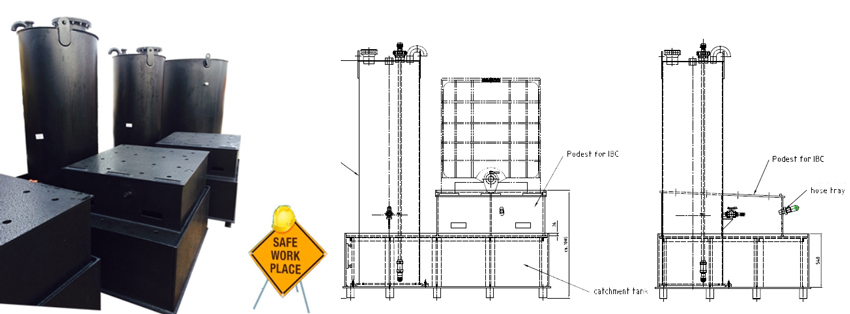

IBC Storage Units – standard

Aggressive fluds are often delivered in pallet tanks (IBC) to IWAKI customers, and particularly the replacement of the empty and a new pallet tank is a rather critical workflow. In this regard, IWAKI recommends an IBC storage unit.

Left: IBC storage unit with buffer / receiver tank in fiberglass with PVC in-liner (for eg, sodium hypochloride) as well as a complete pump cabinet fitted with a SMX-F self-priming, mag-drive centrifugal pump.

Right: IBC storage unit in PE-HD with buffer / receiver tank (for eg. lye).

With IBC Storage Units you can achieve:

- Easy, quick and safe replacement of pallet tanks

- No spillage during the replacemant of the pallet tanks

- Only one-time pump priming required

- Buffer capacity in the IBC Storage Unit ensures continous operation

- Slope of pallet tank ensures complete emptying of the pallet tank

- Integrated collection tray as security for potential leakage in tanks

IWAKI’s standard IBC Storage Units

are delivered primarily in PE-HD material that has excellent resistance to aggressive liquids.

The IBC storage unit consists basically of:

Pedestal for IBC-tank

slope for improved emptying of pallet tank

Max dimensions: 1120 x 1260 x 195/245mm

Collection tray

with enough capacity for the total volume of both IBC and receiver tank.

Max dimensions: 2500 x 1500 x 675/890mm

Buffer-/receiver tank

Buffer volume standard 50, 100, 300 og 500 liter after empty IBC tank

Max dimensions: 2250 x Ø 1200mm

Connection set for IBC tank

Fittings and pipes in PVC

Seals in EPDM or FPM

Customized solutions

If you need a customized solution please let us know.

We have e.g. delivered IBC storage units for food and pharma.

Accessories / options

You have the option to select additional features for the IBC storage unit. For example ultrasonic level meter, leakage sensor, drainage tube with bottom valve, inspection glass, IBC venting kit, complete pump cabinet, manual vacuum lifting device etc.