DOSING PUMPS – dosing accuracy, safety and durability

With a high dosing accuracy and a lifetime up to 20 years, IWAKI dosing pumps are extremely reliable components in your system.

We regularly encounter IWAKI dosing pumps working more than 20 years. The pump design and the selected materials play a very important role in both the durability and also to achieve the highest possible safety when dosing with chemicals.

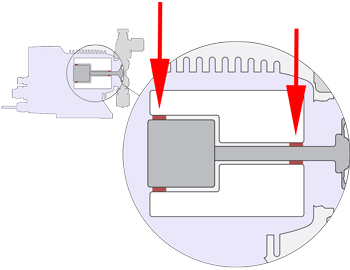

Double bearing of the magnet coil:The IWAKI dosing pumps all have double bearing of the magnet coil, which significantly increases the lifetime of the pump. This solution provides a stable and flawless operation of the “engine” itself inside the pump. |

|

|

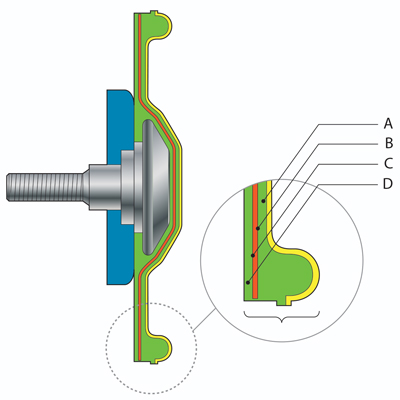

The Diaphragm:The most vulnerable component of the dosing pump is the diaphragm. Due to IWAKIs focus on this component IWAKI has developed a very robust diaphragm ensuring an extremely long lifetime. IWAKI’s diaphragm consist of a special 4-layer construction. A significant detail is the design of the diaphragm supporting plate. A: PTFE All components behind the diaphragm are made of stainless steel or plastic; providing the highest level of security for corrosion damage if chemistry leaks through the diaphragm. |

|

|

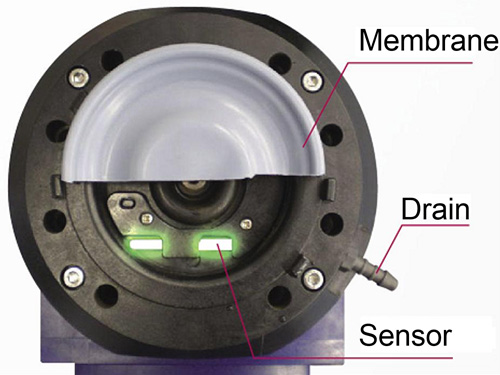

Built-in leakage sensor:The latest metering pumps (IX series) always have a built-in leakage sensor. It allows for an external alarm and pump stop at diaphragm rupture. |

|

|

IWAKI dosing pumps: |

||