Dosing Pumps – 10 tips for your installation

How to ensure optimal conditions for your dosing pumps

1. Place the pump as close to the pallet tank as possible.

2. Provide a short suction hose. For pumps with automatic air vent valves, the suction height must not exceed 1.0 meter.

3. Avoid bends, breaks and air locks in your suction hose.

4. Gas/air needs to be expelled from the pump and tubing by degassing. Normal performance can not be obtained with gas in the pump.

5. Avoid air/gas in the dosing system by replacing the pallet tank before it runs out. A suction pipe with level switch is recommended.

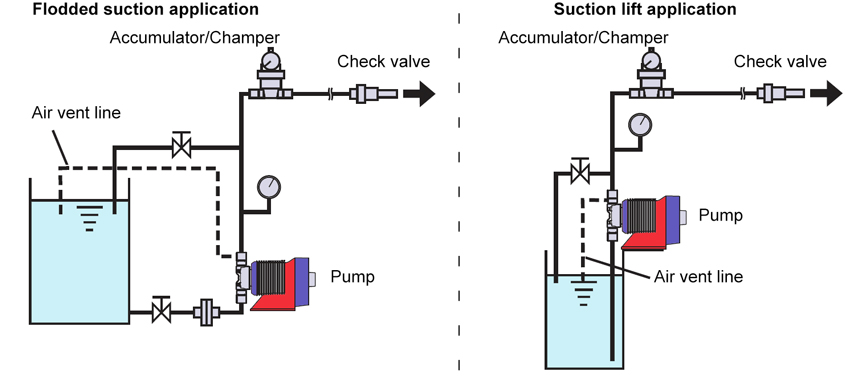

6. Avoid dry running. IWAKI flow-checker ensures stable operation.

7. If the pump has positive inlet, install a valve in the suction line.

8. Positive inlet installation is recommended for liquids with gas.

9. Install a pressure gauge at the pressure side of the pump and, if necessary, install a pulsation dampener at the pressure side to avoid unwanted pulses.

10. Use a back-pressure valve at the end of the pressure side to provide the pump with the appropiate pressure necessary for exact dosing, and preventing fluid returning in the system. (See image above)

Contact us for further information – tel (+45) 4824 2345