PROCESS PUMPS – Tips for your pump installation

Tips to ensure your pump installation optimal conditions = pump life is extended.

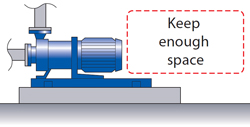

| 1) Install the pump on a flat and sound foundation, free from vibration and in an easily accessible location. Keep enough space around the pump for the back pull-out of motor, assembly and maintenance of the pump.

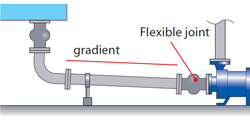

2) Install the pump with the nameplate directly readable a.o. things for service and ordering spare parts. 3) Be sure your suction piping is below your liquid level ensuring flooded suction conditions to the pump at all times. |

|

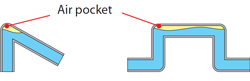

4) Avoid air pockets by having a slight slope of the piping on the suction side. Avoid bends in the pipeline where air can get caught in the piping system. 5) Baffle the interior of your supply tank to prevent swirling and to reduce the flow speed6) Keep the supply tank free from debris that can enter the pump |

|

| 7) Be sure the inlet piping to the pump is the same or a larger diameter than the pump inlet.

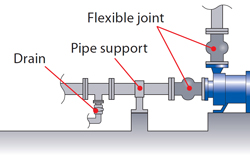

8) Do not allow pipe weigh to the pump inlet and outlet flanges. Install pipe support so that the pump does not support the weight of the pipe. 9) Keep the inlet piping as short as possible but no shorter than 10x the pipe diameter (example a 2” pump suction should have 20” of straight pipe heading into the pump inlet). 10) Minimize the number of joints on the suction line and be sure all joints are completely sealed. 11) Ensure good drainage options for complete emptying of the pipe system. |

|

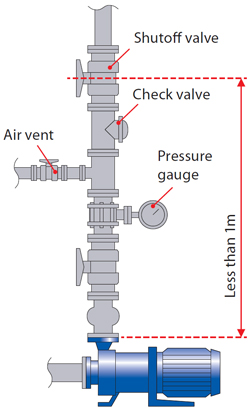

| 12) Install shutoff valves (gate valves) for maintenance and inspection work. Shutoff valves on suction pipes should be fully opened during operation. It is recommend to keep 1 m distance between the pump discharge and the shutoff valve.

13) Install an air vent valve on the discharge to purge any air on the discharge upon startup. 14) We recommend the installation of pressure gauges on both suction and discharge side of your pump system, which gives you an idea of the pressure of the pump and thus the flow. 15) Build your pump system so that it can be flushed with water before disassembly for service. Remember to make sure that the media and water can be mixed without chemical reaction. 16) Take into account the temperature fluctuation when your pump installation is established. Temperature can change the viscosity and density of the medium, which affects the pumped capacity. 17) If your liquid crystallizes at low temperatures (such as lye), we strongly recommend that you isolate – and possibly heats – your installation. |

|

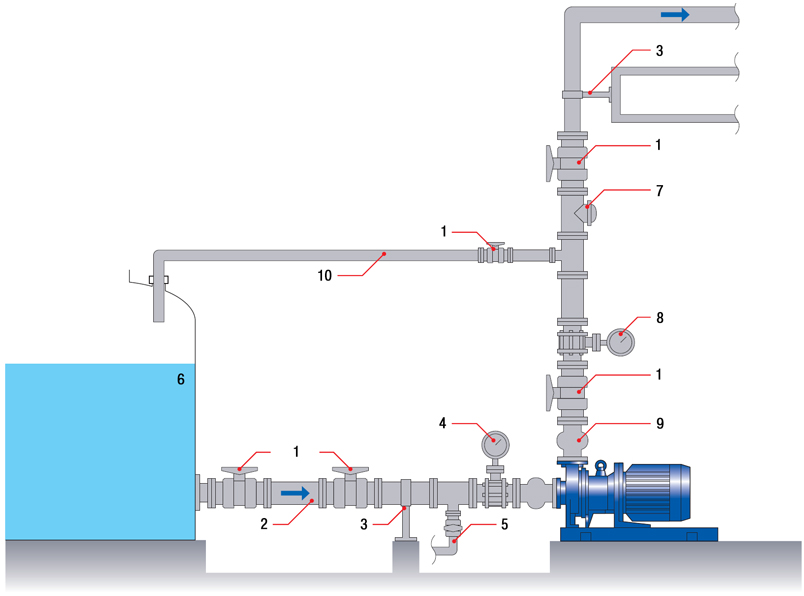

Recommended pipe layout example |

|

|

|

| 1. Valves | 2. Suction pipe | 3. Pipe support | 4. Vacuum gauge | 5. Drain 6. Tank | 7.Check valve | 8. Pressure gauge | 9. Expansion joint | 10. Air bleed line |

|

| Contact us for further information Phone: (+45) 4824 2345. |

|