Centrifugal pumps

Abnormal Operating Conditions – “Dead Head” and “Cavitation”

For many years, IWAKI has focused on eliminating the consequences of “abnormal operating conditions” and has developed and patented several good solutions.

“Abnormal operating conditions” can be harmful to a pump and lead to expensive downtime, no matter if the pump has magnetic drive (like IWAKI pumps) or if it is a traditional pump with shaft seals.

“Dead Head Running”

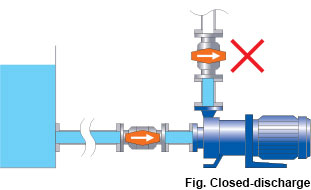

The “Dead Head” phenomenon occurs in situations where the pressure side of the pump is closed, either due to a blockage or a closed valve.

If the pressure side of the pump is closed (see the picture below), the liquid will still circulate inside the pump without the possibility of “getting out”. In this way, all the energy is transferred to the liquid. Sooner or later, frictional heat will increase to such an extent that it may destroy the pump.

IWAKI’s “Self-Radiation Structure” can counter this problem (see below).

“Cavitation”

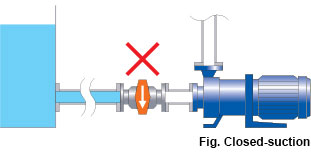

If the suction side is closed or partially blocked (see picture below), the pump will start to cavitate almost immediately. During cavitation, pump performance is reduced, and vibration and noise occur.

Cavitation occurs when the pressure in the liquid is so low that small steam bubbles appear in the liquid immediately in front of the pump inlet.

When the liquid, incl. small bubbles, enters the pump, where the pressure is higher, the bubbles will implode (collapse). This will create vibrations that may eventually cause damage to the pump.

Cavitation also produces noise; from a quiet crackle to an outright “bang”, sounding like fireworks or gunshots, depending on the size of the pump.

IWAKI’s “Self-Radiation Structure” improves the pump’s ability to resist the effects of cavitation (see below).

”Self-radiation structure”

Heat drainage holes provide lubrication and cooling

IWAKI has developed and obtained a patent for the construction “Self-radiation structure”; the pump bearing is equipped with small heat drainage channels. The channels improve the internal liquid circulation and ensure that the pump parts are lubricated and cooled – even under abnormal operating conditions such as cavitation and “Dead Head Running”.

IWAKI has incorporated the “Self-Radiation Structure” in all versions of the MXM pump series. However, IWAKI emphasizes that the suction side should always be completely open, and the discharge side open sufficiently to maintain the required flow.

IWAKI recommends always to pay attention to ”abnormal operating conditions” and to take appropriate precautions.

See the video: “IWAKI’s Self-Radiation Structure” Click here.