Magnetic drive pumps

Abnormal Operating Conditions – Dry running

For many years, IWAKI has focused on eliminating the consequences of “abnormal operating conditions” and has developed and patented several good solutions.

“Abnormal operating conditions” can be harmful to a pump and lead to expensive downtime.

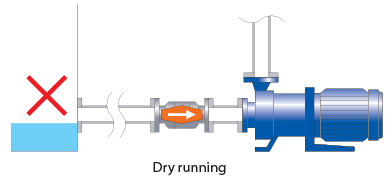

Dry running

You will avoid friction heat in IWAKI’s “Non Contact System”

Dry running means that the pump runs without liquid, which can be incredibly harmful for all centrifugal pumps – both pumps with shaft seals and magnetic drive pumps.

n normal operating conditions, the liquid circulates in the centrifugal pump and provides cooling and lubrication of the pump. Without liquid, frictional heat may be generated, causing the pump to overheat, and thus damaging the impeller, bearing, shaft and pump casing.

To counter this, there are a number of solutions; most commonly used are various monitoring systems that trigger an alarm in case of dry running.

With IWAKI’s patented “Non-Contact System”, frictional heat is completely avoided, as the inner and outer magnets are designed in such a way that the inner magnet is held in place even during dry running. Thus, contact does not occur between rotating and fixed (static) parts, and frictional heat is thereby avoided.

IWAKI’s “Non-Contact System” has been implemented in MXM and MDM pumps, even in combination with carbon bearings, which have excellent self-lubricating properties themselves. It minimizes friction even during dry running.

The pump can therefore withstand running without liquid for a long time, in some cases up to a few hours, without damages of any kind. This is documented i.a. in this video, where an MDM32 pump from IWAKI is tested without liquid.

However, IWAKI recommends that you continue to be aware of “abnormal operating conditions” and take appropriate precautions.